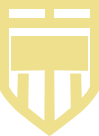

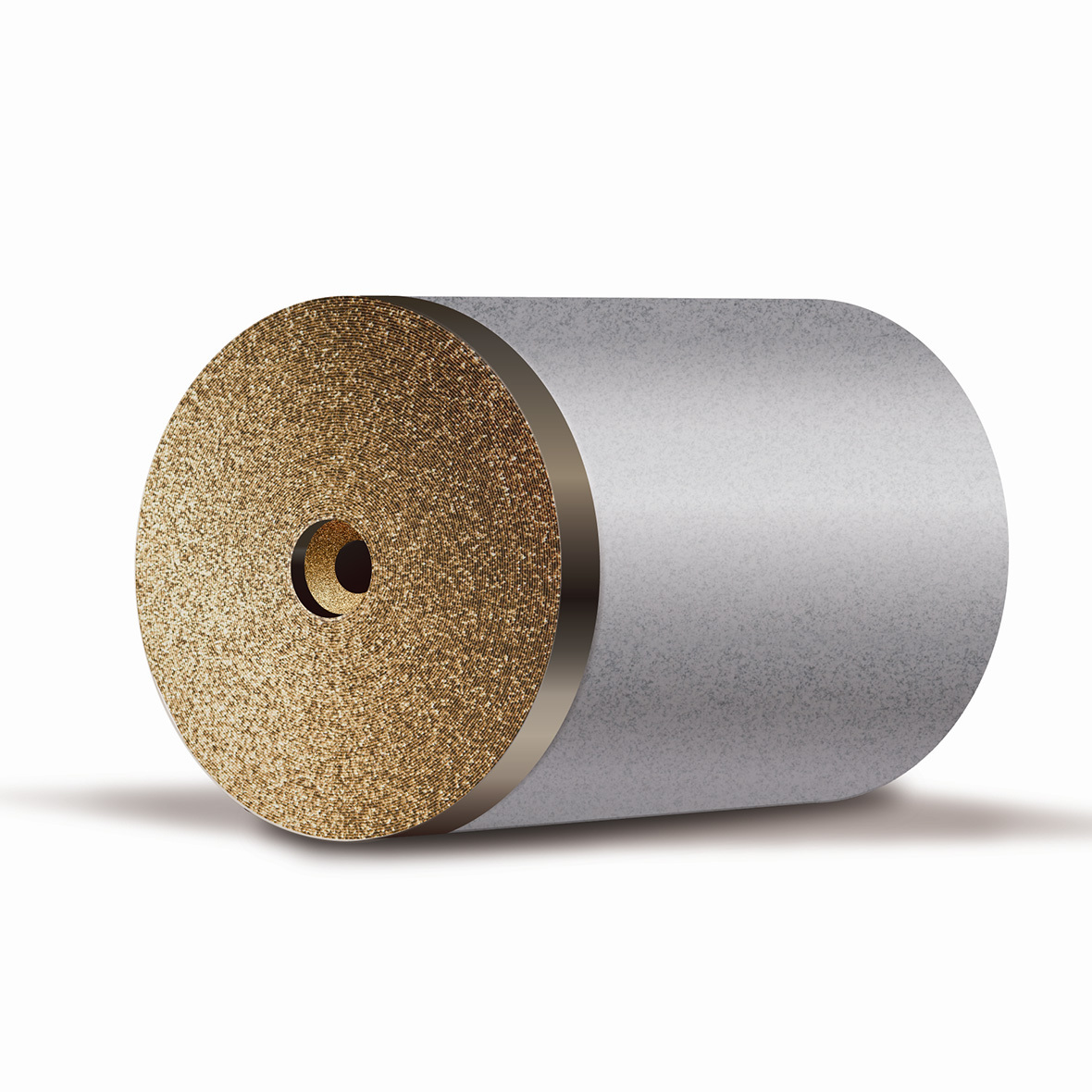

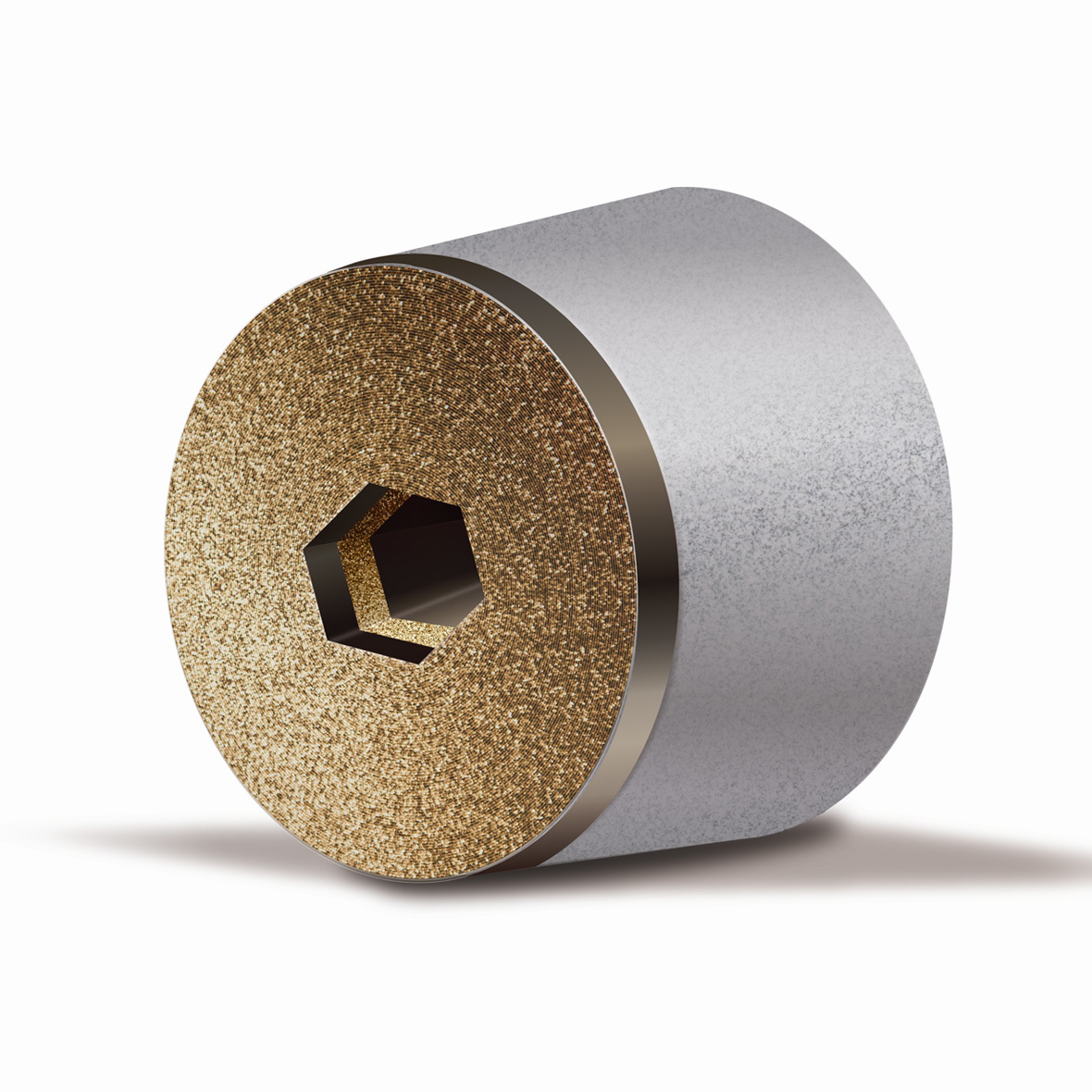

Gradient alloy drill point die

Solve the contradiction between the performance of traditional tungsten steel. Focus on die materials for cold heading and forging industry.

keywords:

Category:

Products

Hotline:

Product description

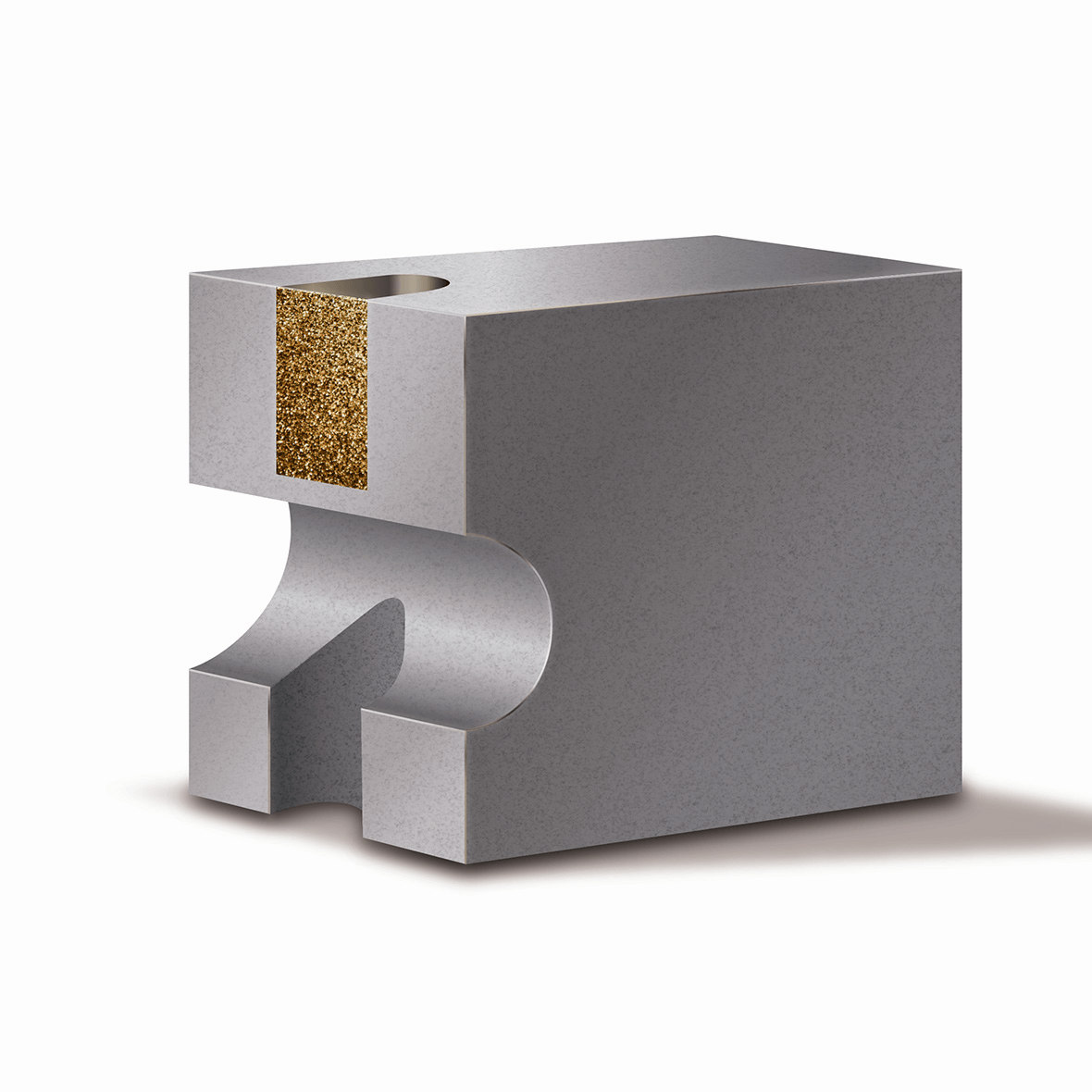

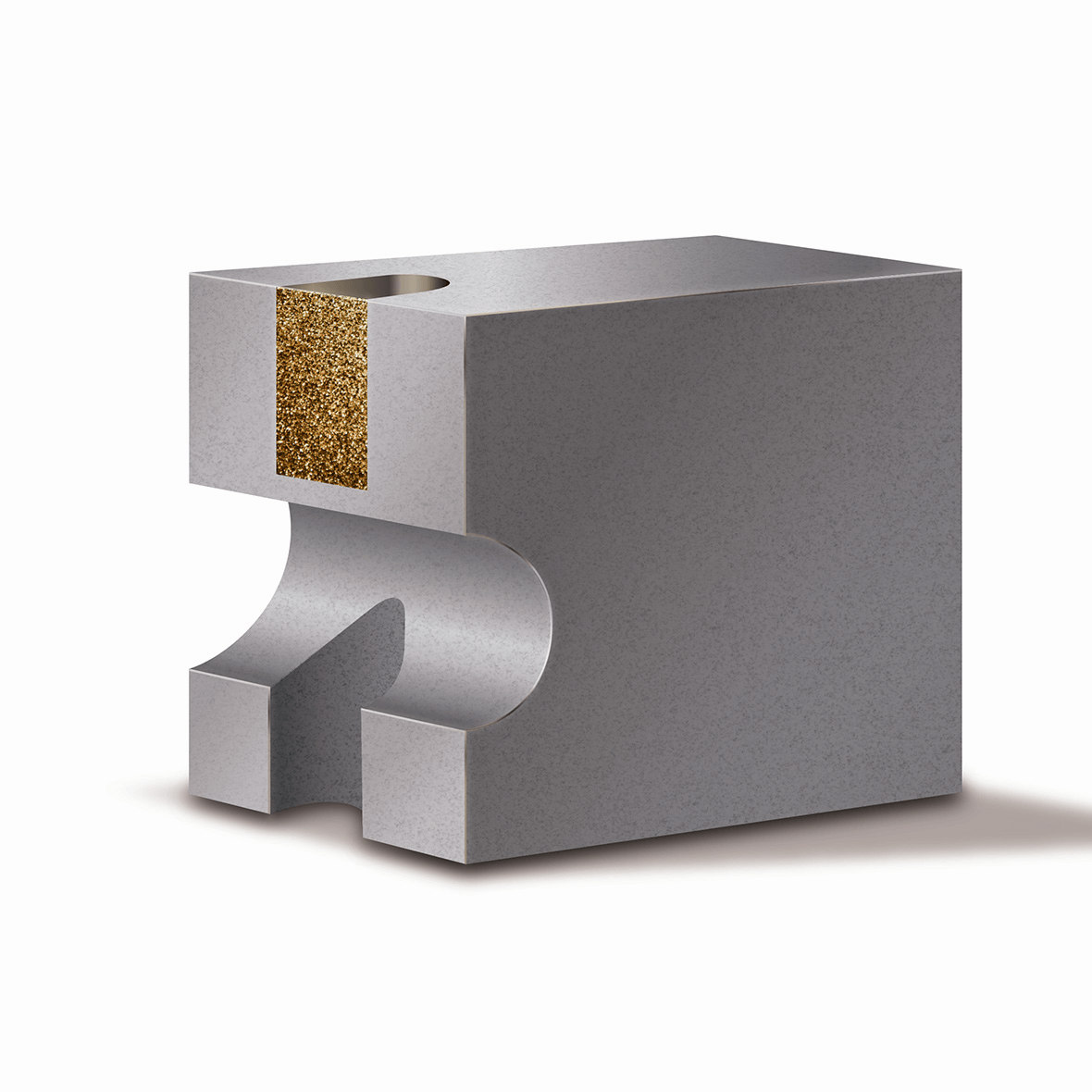

Gradient alloy drill point die

Please provide the mold surface and the hardness and wire material of tungsten steel, and inform the mold failure situation and damage position, so that our company can adjust the design gradient layer (local decarburization treatment).

Gradient alloy drill point die

Please provide the mold surface and the hardness and wire material of tungsten steel, and inform the mold failure situation and damage position, so that our company can adjust the design gradient layer (local decarburization treatment).

What is graded alloy?

Gradient alloy is the high performance cemented carbide with multi-layer gradient structure. In nature, bones of the animals are the type of gradient structure with hard outside and soft inside.

This principle is able to effectively solve the obstacle that the material with single hardness is apt to be damaged. When the tungsten steel material is subjected to impact, the impact stress is rapidly released and buffered.

Why is it able to prolong the service life?

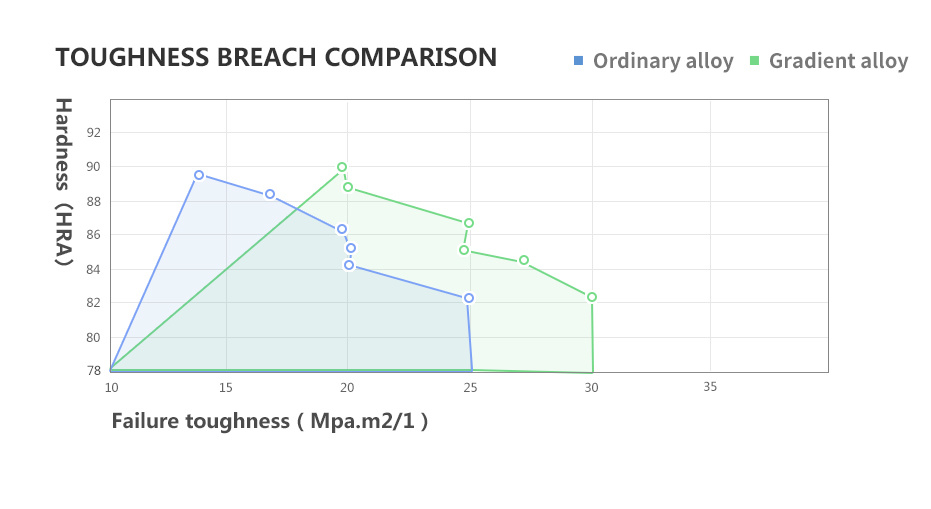

The higher the hardness of the conventional tungsten steel,the worse the toughness and the easier the breakage.

The lower the hardness and the less wear-resistant allows the service life to fail to meet the requirement.

Gradient alloy easily solves the performance contradiction of the traditional tungsten steel, so that it can possess high hardness and high toughness simultaneously.

Make moulds resistant to impact and abrasion! Make up for the defect of excessive gravity load of the forging design. (The service life exhibits 3 to 6 times of growth)

Comparison of fracture toughness(KIC)

Previous

Next

Previous

Next

Related products

Product message